Preliminary Study for Leakage Detection System

Indonesia’s energy consumption is using 95% fossil fuels and considered as a country with a fairly high level of energy consumption. Currently, Indonesia is in the state of energy crisis with oil reserves of 3.7 billion barrels, or 0.3% of world reserves. Leakages in oil piping system are among one of the major problem responsible to the lack of energy resources in some areas. This research aims to apply leakage detection system on pipeline based on acoustic and vibration methods.

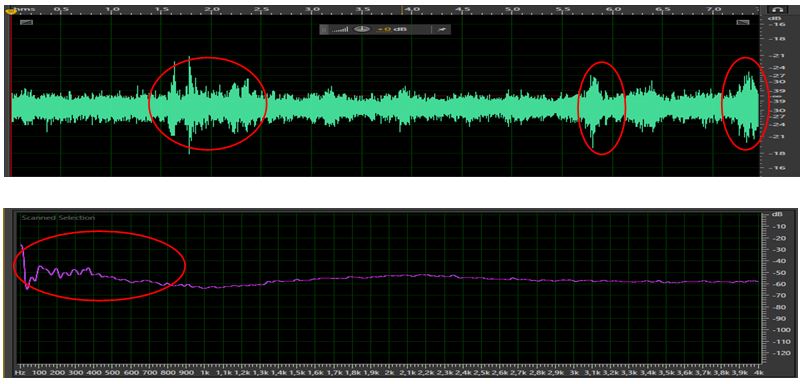

The recording data in the acoustics method was done by putting a microphone with an angle of 45º, 90º, and 180º against the source of leaks. The data recorded is displayed by signal Real Time Analyzer which then converted into the frequency domain. Meanwhile, the vibration method is done by putting the piezoelectric sensors on the pipe surface to record the vibration signal. The recording is done by conducting a variation on the leak hole diameter (5 mm, 6 mm, and 7 mm) and the placement distance of sensors from the leaking holes (10 cm, 20 cm, …, 70 cm). The signal is recorded in unit of bits, then converted into voltage. The average value of the data plotted for a pipeline without leak hole shows linear form and non-linear for pipeline with leakage. This research is expected to be a pioneer in detection system and monitoring of any type of liquid piping distribution system. For future development, a tested tool it is expected to be created and use for many types of piping distribution.

From left to right : Randy Frans Fela, Lisa Fita Sari, Nur Chalim Wachidah, Zulfi Aulia Rahman

From left to right : Randy Frans Fela, Lisa Fita Sari, Nur Chalim Wachidah, Zulfi Aulia Rahman